how we do things

We do things a little different. Not only do we design everything ourselves, we also only build bikes to order. And we have no model years, our bikes keep their value.

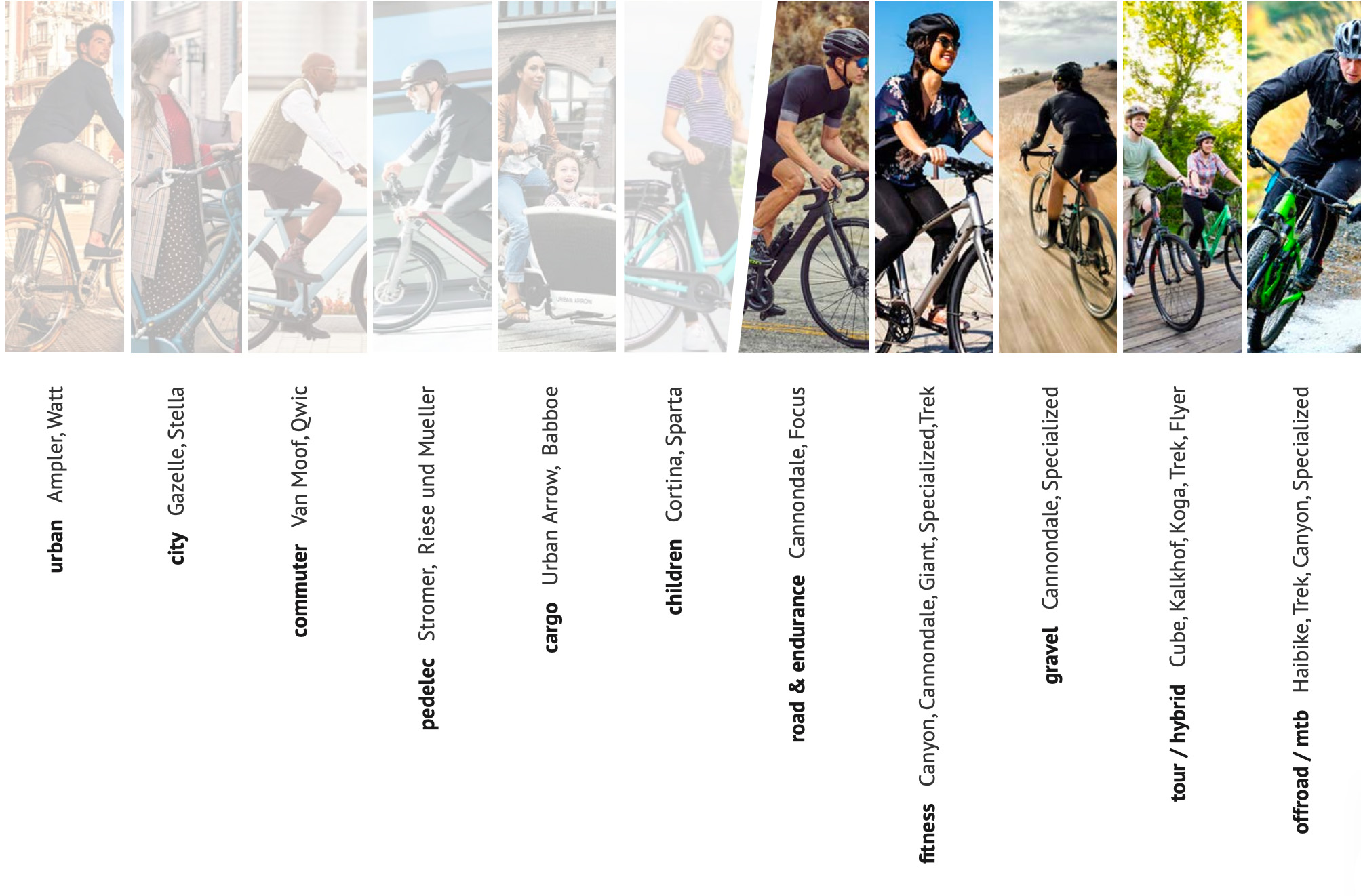

built to order

Our bikes are unique, built one by one by hand and are expensive for that reason.

We spend a lot of time on development, innovation and quality. We design our bikes from the ground up, including kinematics, geometry, drive system integration and much more.

Everything we do is small scale and done by hand. We build bikes one by one for our riders, according to the configuration they choose. Bearings we press ourselves and also the preparation of the raw carbon parts for coating we run in-house. Coating is done at a local coating firm.

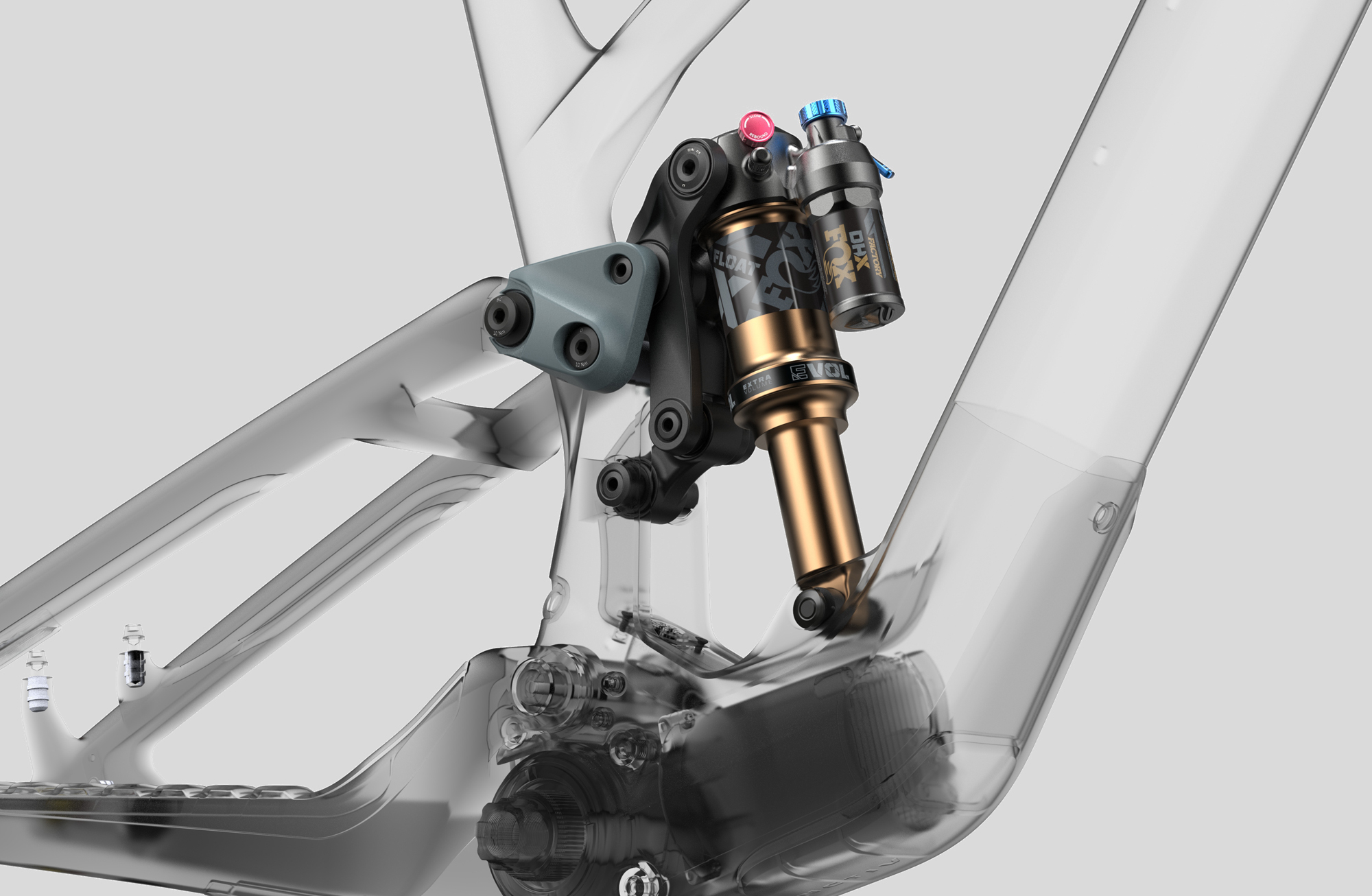

And finally we work with high-end components, as we believe they help define the ride and quality of a good bike. Components that are durable and of high quality, like Swiss made Maxon drive units, DT Swiss wheels, Fox suspension components, Magura brakes or Pinion gearboxes. They will last a lifetime, as goes for our full carbon frames.

no model years

It is quite normal in the bike industry to use model years. We do not do that. Our bikes keep their value, does not matter if they are build this year or a few years ago.

We innovate all the time. New upgrades will be available as parts, mostly with backwards compatibility. This helps to keep your bike up to the latest standard if you would want that.

replacement parts

If your frame or parts of your frame got damaged beyond repair, we can help you with crash replacement parts. This goes both for rockers, links, pivot bolts and axles, but also for carbon parts.

We will have the parts coated in the color of your bike, send you all parts you need and with our help you can fix your bike and make it like new again.

design of a new bike

When we start development of a new bike, we first of all think about what riders would enjoy. The purpose of any bike we design is always to give you fun on the trails and inspire you to go out in nature, enjoy the adventure and feel free.

We design trail and enduro bikes for natural trails. Bike that are confidence inspiring for new riders and offer great speed and fun for more experienced riders.

Once the idea is there we start off with the first step: to create a solid design strategy.

strategy

When we start a new bike design project, we first do our home work. Obviously we know a lot of what is going on in the industry, but still we start off with research.

We speak with riders and dealers, check the newest roadmaps from component partners, scan what other manufacturers are doing and ride competitive bikes. This helps us to find opportunities for innovation and bike design.

This is also the moment we develop early idea’s about geometry, kinematics, drivetrain and components. And last but not least, we use some powerful design tools to create early idea’s about the new design language for the bike, without even making a single sketch yet.

All this information together in a strategy document serves as a guide throughout the project.

kinematics and geometry

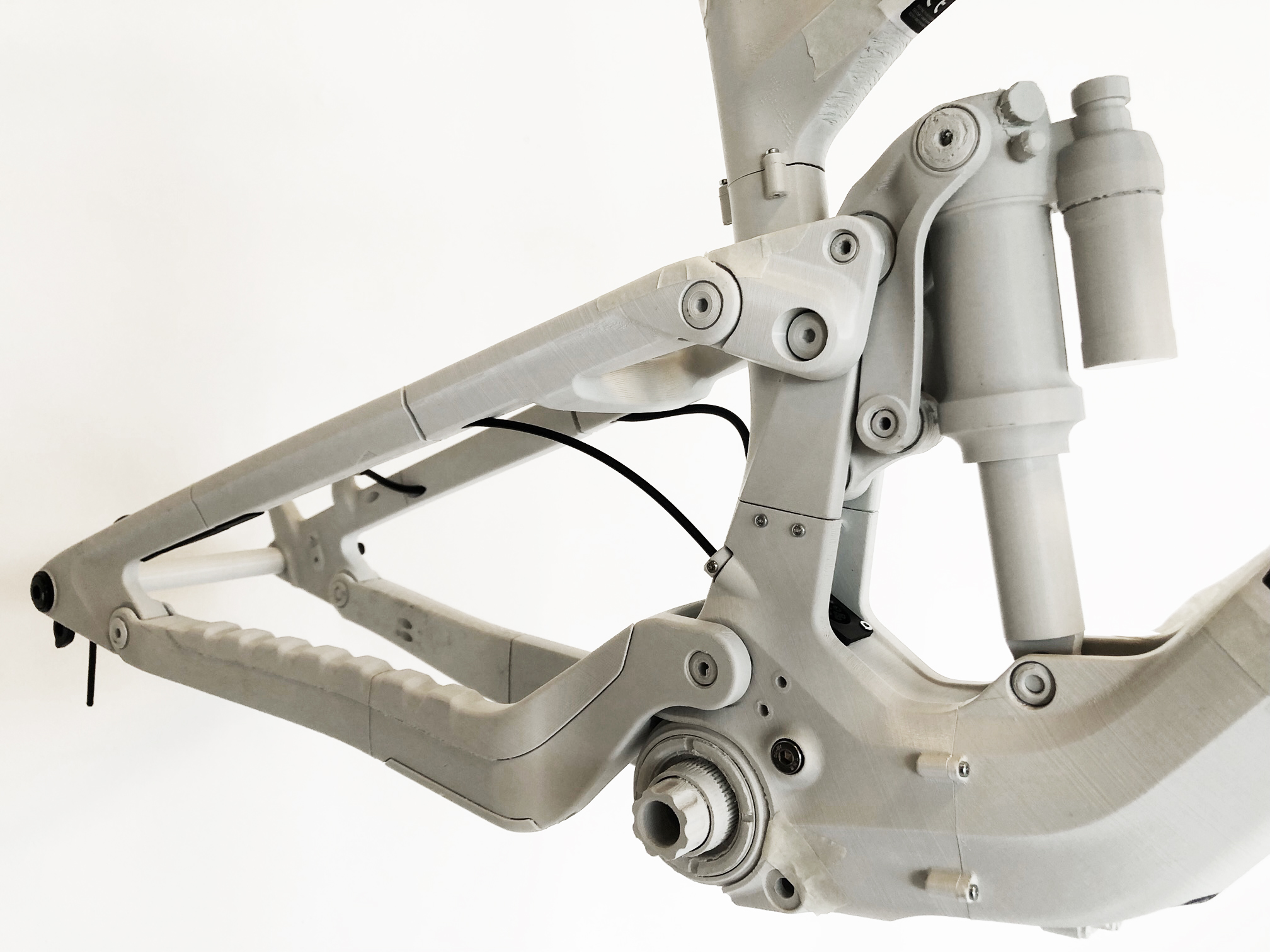

Geometry and kinematics are extremely important factors of the early bike design. With the early idea’s of geometry and kinematics we set to work. We build early 3D CAD models of the draft suspension setup, with rockers, axles, links, bearings and run many simulations to see if we can find something that fits and that we really like.

We do not only simulate and test in CAD, but also ride bikes, test with mules and create prototypes that help us develop geometry and kinematics that best fits the new bike. Development is not a straight line, it comes in circles of simulations, create in CAD, testing with prototypes and back to simulations again.

concept development

At the same time when we are working on the kinematics, geometry and early 3D CAD setup for the suspension parts, we also work on the general look and feel of the bike. This is really still handwork, creating a lot of sketches, which are getting better and more realistic step by step, as more information is coming in where the actual pivot points will come and how the suspension will work.

Many walls in our design studio are full with sketches of the bike frame. The more we come to idea’s we like, the more detail we will add, both in the frame itself, but also supporting components, to get a good overview of how the full bike will look like. This is also the moment to make some full scale side view prints of the bike, to check the look and feel in real size conditions.

engineering

The first important milestone during the design of a new bike is to bring the concept to a first fully functional carbon prototype, which we call the P1.

To do so, we use powerful 3D CAD software to create a detailed model the bike frame: all carbon parts, pivots, bearings, rockers and components like shocks, forks, motor and battery.

To achieve maximum performance at minimum weight we use 3D CAD simulations and run tests with early prototypes.

In addition to a complete set of 3D CAD files, we create a bill of materials and a full set of 2D drawings during the transition to production of the first P1 prototype.

prototyping

Both during the concept and engineering phases we build prototypes. Early prototypes are mostly more like mockups and are often 3D printed. We use them mainly for testing shapes, ergonomics and engineering solutions. Also these prototypes are good to test the fit of motors, batteries, cables and seat tube. At the end of the engineering stage we build the first carbon P1 prototype bike. This is done in cooperation with one of our carbon manufacturing partners.

We use this P1 prototype bikes to test performance, kinematics and durability. We take the bikes to the trails in Alps, Croatia and Slovenia and test them to the limits. During the testing period we document all the improvements and make updates in the CAD files where needed. This will lead to an updated prototype P2. These prototypes are used as well for ISO4210 testing and further heavier factory testing. Now the bikes are ready to show to the public and move slowly to production.

testing

For extensive performance testing we use our locations in Croatia and Slovenia. If frames and components survive the extremely rocky and technical natural trail there, they will pretty much survive anything.

We ride prototypes on Alpine trails in Jamnica (SI) and on the trails of UCI Premantura (HR), UCI Kamenjak (HR) and Rabac (HR). Apart from these testing locations, we have test riders in Switzerland participating in Enduro races.

made in Europe

Most of our production steps are done in Europe, we actually add about 65 percent of the production value in Europe. Many high-end components that we use on our bikes are made in Europe as well.

We build our bikes completely in-house with our own people. Only the raw carbon parts come from a premium carbon frame manufacturer in Asia.

We check the quality of all parts in-house, have the coating done in Europe and also do the full assembly our frames in house with our own quality system.